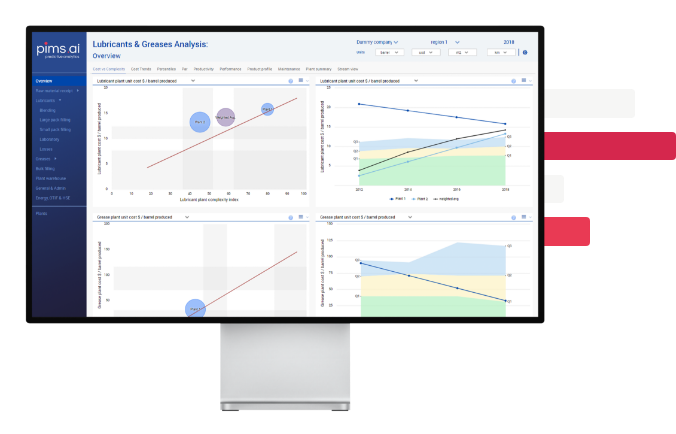

The PIMS® Global Lubricants and Greases Supply Chain Benchmarking.

For over 30 years PIMS® has been benchmarking the supply chain of lubricants and greases plant operations. Currently our project covers over 50% of the global annual throughput. Hence it has become the industry standard for assisting companies in optimising their supply chain by learning from appropriate comparisons. To find out more about the project in detail, please have a look on our brochure.

Use cases.

PIMS helps to bring about change by providing a common language between operating units, showing priority areas of focus, setting targets and surfacing ideas for improvement. PIMS facilitates an excellent benchmarking process and builds cost consciousness.

Our repeated participation in the PIMS benchmarking study has been one of the most successful decisions we have taken.

PIMS is a critical enabler to highlighting areas of competitive advantage by site and operating area, making transparent our real performance against internal and external comparators.

For the first time we have a clear picture of where our competitive position is on costs. This will lead to actions to improve our position.

Our participation in the PIMS Benchmarking study has literally forced us to measure business areas that were previously overlooked, and has given a clear indication of the strengths and vulnerabilities in our operations. The study has provided our personnel with a deeper and stronger knowledge of their respective operations and made them more accountable over their own results.

PIMS benchmarking has greatly aided our continuous improvement. It guides us from our current status to our desired goals.

PIMS helps to bring about change by providing a common language between operating units, showing priority areas of focus, setting targets and surfacing ideas for improvement. PIMS facilitates an excellent benchmarking process and builds cost consciousness.